MODBUS Differential pressure / Volume flow controller for HVAC - DPC200-MOD

Differential presssure / volume flow controller

Electromechanical diaphragm measuring system

Configuration via Modbus communication

Selectable measurements (differential pressure or volume flow)

Selectable units (Pa / InH20 or m3/h or cfm)

Selectable control mode or measuring mode

Control mode with adjustable: setpoint, maximum output voltage, P and I parameterd for PI-algorithm, direct or inverse sense

Adjustable k-factor for volume flow calculation

Analog output 0…10 V

Alphanumeric LCD-display

Supply voltage 22…26 Vdc; 24 Vac (+/-10%)

Compact plastic housing IP 54

The DPC200-MOD has been developed to bundle functions needed in the HVAC industry into one device. As a precise differential pressure sensor it can transmit measurements for both pressure and air flow. The integrated PI control logic is an important component in decentralized closed loop control systems, where pressure and air flow have to be constantly controlled.

The additional Modbus RTU interface is intended for the digitalisation of industrial processes. All device parameters can be read and written with the Modbus RTU interface.

For direct analog processing, a 0 … 10 V signal output is available. This signal can be configured as a linear / square root measuring signal, or as a manipulated variable of the closed loop controller.

It can be used, for example, in air-conditioning technology for controlling fans, monitoring room pressure or controlling filters.

Operating mode:

Measuring mode or control mode

Measuring medium:

Air or non-aggressive gases

Measuring principle:

Electromechanical diaphragm measuring system

Measuring unit:

Pa / inH2O or m3/h or cfm

Smallest measuring range:

0…50 Pa (0.5 mbar) / 0.2 InH20

Largest measuring range:

0…6000 Pa (60 mbar) / 24 InH20

Measuring range:

0…50 Pa (0.5 mbar), 0…100 Pa (1 mbar), 0…500 Pa (5 mbar), 0…1000 Pa

(10 mbar), 0…2000 Pa (20 mbar), 0…4000 Pa (40 mbar), 0…6000 Pa (60 mbar)

Measuring range selection:

Factory preset

Adjustable controlling parameters:

P/I – parameter, k-factor, maximum output voltage, normal/ inverse control

Characteristic:

linear for pressure measurement, radiated for volume flow measurement

Ambient temperature:

-10…+50°C

Storage temperature:

-25…+60°C

Control characteristic:

PI – algorithm

Setpoint settings:

2 setpoints can be set via keys, selection of setpoints via potential free contact

Protocol:

Modbus RTU

Baud rate:

selectable in menu, 7200…57600

device adress / ID:

selectable in menu, 1…247

Parity check:

selectable in menu, none, even, odd, none2stopbits

Telegram structure:

8 Bit ID; 8 Bit FC; 16 Bit DA; 16 Bit D; 16 Bit CRC

Overpressure protection:

0.2 bar

Static pressure:

max. 0.2 bar

Zero point calibration:

Adjustable by REEDcontact, no cyclic zero-point calibration required

Reaction time:

direct

Zero drift:

±0.75%

Sum of linearity and hysteresis:

± 0.5 % … ± 1 %

Temperature drift zero point:

±0.3% / 10K

Temperature drift measuring range:

±0.2% / 10K

Housing:

UL 94 HB; Ultramid with hinged lid of ABS

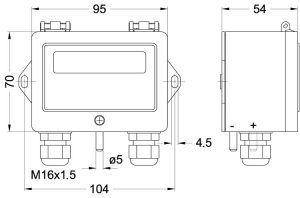

Dimensions:

95 x 70 x 54 mm (w x h x d)

Weight:

approx. 250g

Protection class:

IP54 according EN60529

Display:

Two-line alphanumeric LCD display, 2 x 16 characters

Electrical connections:

Cable entry M16x1.5, screw terminals, electronics protected against incorrect polarity

Cable entry:

2 x M16

Pressure connections:

Hose connections 5 mm ø and 6 mm ø

Operational position:

Vertical, position dependence when rotated through 90 ° approx. 25 Pa

Power supply:

22…26 Vdc; 24 Vac (±10%)

Power consumption:

approx. 50 mA @ 24 Vdc; < 2 W Power

Output:

0…10 V; Imax= 1.0 mA, Rmin = 10 kΩ

EMC:

EN 61000-6-2, EN 61000-6-3, CE-mark

RoHS:

According RoHS-directive 2011/65/EU

Are you interested?

Leave us a message and we will get back to you as soon as possible.