APPLICATION

THE SPECIALISTS FOR MEASURING & CONTROLLING CLIMATIC CONDITIONS.

We produce high-precision equipment so you can accurately determine low pressure, humidity and temperatures. Our devices can be used wherever air currents influence the climate. We are particularly strong in the field of low pressure with precise sensors and controllers for monitoring ventilation systems. Pressure or volume flow can be measured at various points, or controlled in combination with blowers, for example.

Industry

clean rooms

farming

Offices & Hotels

data centers

Industry

Offices & Hotels

clean rooms

data centers

farming

Over the years, our products have been optimised to work perfectly in a wide range of environments. In many situations, they are the measuring and control devices for blowers, fans, heaters, air humidifiers, dehumidifiers and other climate regulators.

Together with our partners, we thus ensure optimum indoor climate conditions.

– Waste heat in industry and data centres

– Particle-free environments in clean rooms

– Optimal living conditions in fattening farms and greenhouses

– The right temperature and healthy air in hotels & offices

We cannot create climate, but we support the professionals to find the right climate and to keep it continuously. We succeed in this thanks to our renowned partners.

Over the years, our products have been optimised to work perfectly in a wide range of environments. In many situations, they are the measuring and control devices for blowers, fans, heaters, air humidifiers, dehumidifiers and other climate regulators.

Together with our partners, we thus ensure optimum indoor climate conditions.

– Waste heat in industry and data centres

– Particle-free environments in clean rooms

– Optimal living conditions in fattening farms and greenhouses

– The right temperature and healthy air in hotels & offices

We cannot create climate, but we support the professionals to find the right climate and to keep it continuously. We succeed in this thanks to our renowned partners.

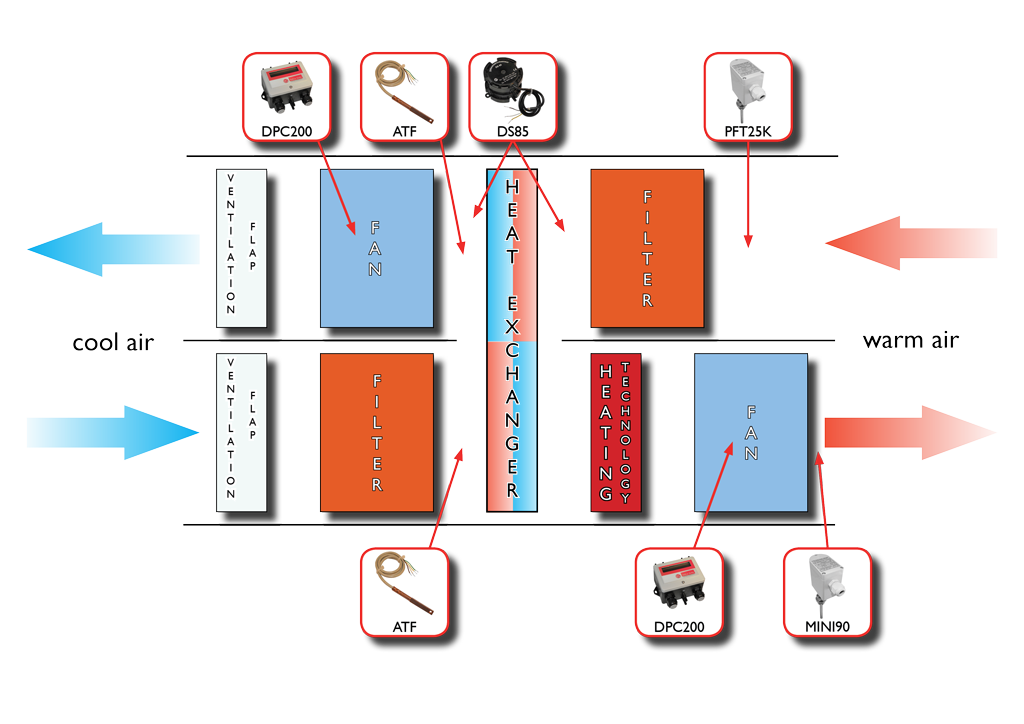

Possible applications in a ventilation system

The differential pressure sensor – DS85 is a robust and compact low pressure sensor. It is our device for universal use. Thanks to the mechanical measuring mechanism, it is particularly resistant to interference. In combination with its IP65 ABS housing, the device also has an exceptionally long service life.

In the systematic representation of a ventilation system, the DS85 measures the differential pressure in the heat recovery unit and simultaneously monitors the upstream filters within the system.

The differential pressure controller – DPC200 can be installed as a direct control module on the blower. In order to control the blower independently, the unit measures the differential pressure or volume flow (depending on demand) upstream and downstream of the blower to ensure continuous air flow. In this way, the energy consumption of a blower can be optimised directly.

The differential pressure sensor – DS85 is a robust and compact low pressure sensor. It is our device for universal use. Thanks to the mechanical measuring mechanism, it is particularly resistant to interference. In combination with its IP65 ABS housing, the device also has an exceptionally long service life.

In the systematic representation of a ventilation system, the DS85 measures the differential pressure in the heat recovery unit and simultaneously monitors the upstream filters within the system.

OEM-manufacturer

Would you like to sell high-quality sensors and control modules under your brand name or install them in your products? You are very welcome, because we are the perfect partner for you!

In our 100-year company history, we have been developing and producing for many well-known companies for many years. Our sensor products are in great demand, especially differential pressure, temperature and humidity sensors. In these areas we develop and produce devices as individual single or series solutions. In addition to national companies, our OEM customers are also globally operating companies that require high-quality and durable sensors or control modules for their product range.

As an OEM customer, we already involve you in the development process of a product. Right from the start, we try to adapt the product to your needs. We attach great importance to flexibility and keep an eye on your time and cost schedule.